Wooden hangers are common items that not only serve the purpose of hanging clothes but also enhance the aesthetic of a space. The production process of wooden hangers is an important aspect of ensuring the creation of high-quality products.

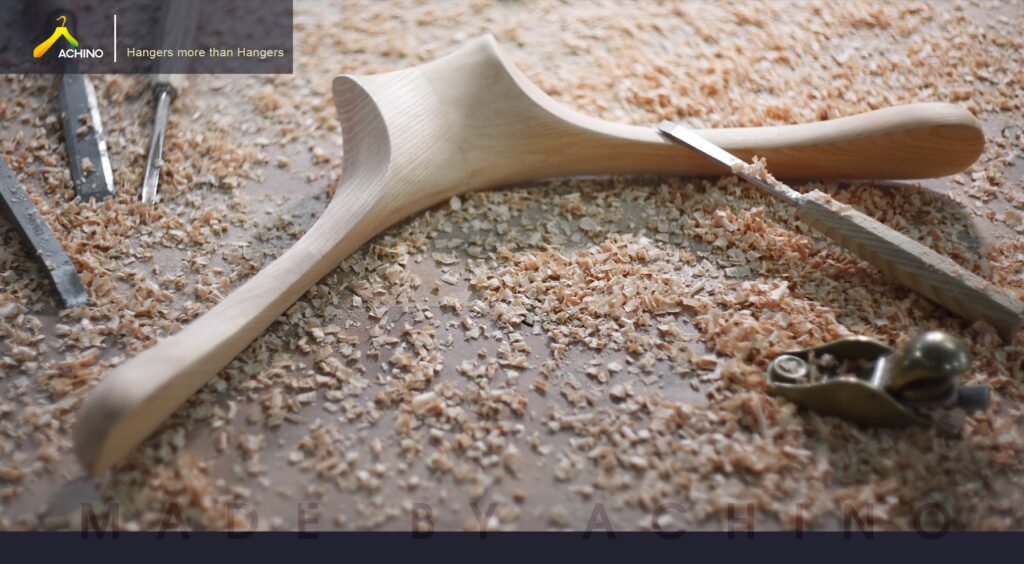

When the production plan is issued, the woodworker will cut the ready wood according to the sealed sample. When cutting the wood, the woodworker needs to consider materials utilization and the production process. After cutting the wood, the woodworker will sand and refine the edges to ensure that the surface of each wooden board is smooth and free of burrs.

The woodworker then assembles the wooden hanger according to the samples. The wooden boards are arranged and combined to determine the shape and size of the hanger. During the assembly process, the woodworker pays strict attention to the length and width of the wooden boards to ensure that each board is precisely positioned and angled to ensure the stability and aesthetic appeal of the wooden hanger.

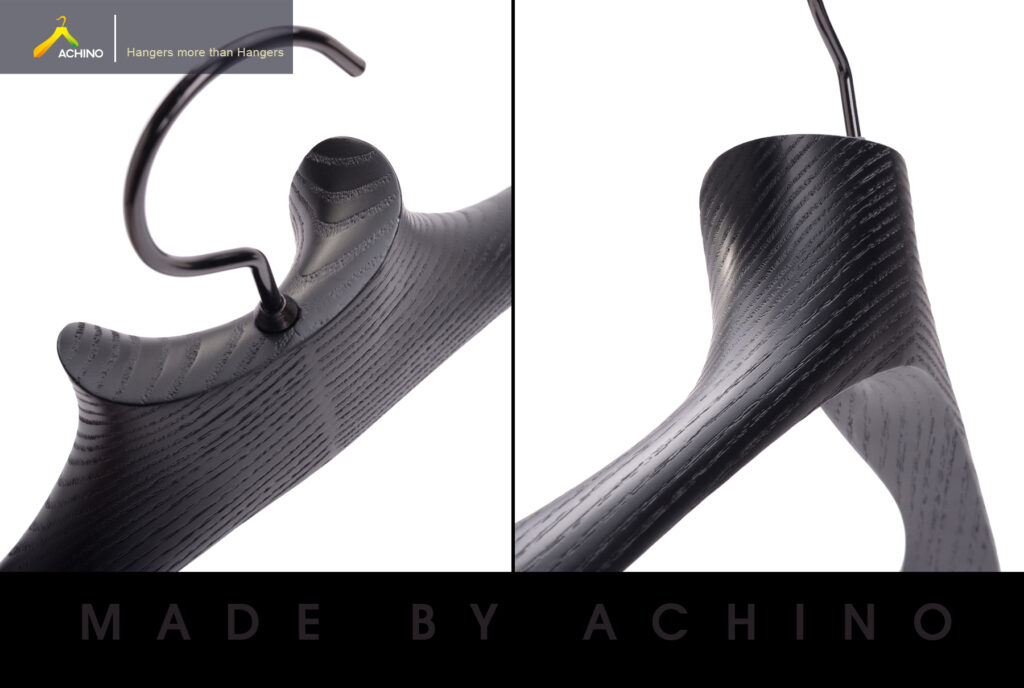

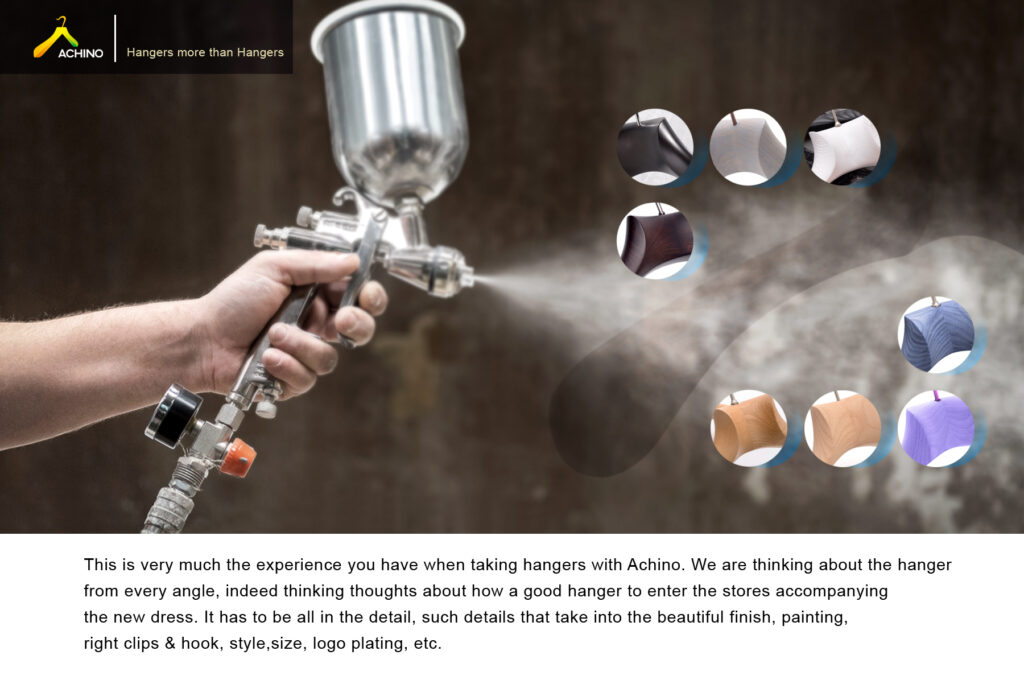

After assembling, the rough wooden hanger will be passed to the sanding workshop. The woodworker uses sandpaper of different grits to ensure the smoothness and texture of the surface of the wooden hanger. Then, the fine-sanded wooden hanger will be put on the automatic painting line. The digital control painting machine will ensure the thickness and uniformity of the finish to guarantee the smoothness, aesthetic appeal, and protective quality of the wooden hanger.

All the details from the selection of materials to the mastery of production techniques, from the retionality of the design to the quality of the paint. Each aspect of the production process must be meticulously handled. Only through the pursuit of perfection in each detail can a high-quality wooden hanger be created.